Engines

Engines

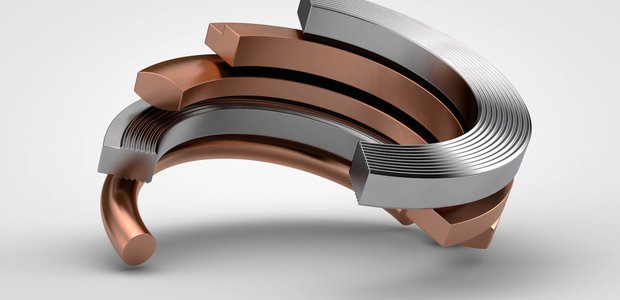

Seals play an indispensable role in the area of vehicle engines. They prevent operating materials, hot gases from the combustion process and lubricants from leaving their designated paths. In this way, they guarantee a permanently high unit performance and ensure a long service life at the same time. To some extent, they also serve as force transmission elements and have a great influence over the distribution of force throughout the tension system and the resulting elastic deformations of components. Furthermore, a functioning sealing system ensures that no harmful substances escape from the engine and get into the environment.

HUFA produces a wide variety of metal seals for engines, including flat seals, profile seals, injector spacers and bonded seals for various applications such as spark plugs, chain tensioners, high-pressure pumps and oil, coolant and fuel lines.

Areas of application – engines

- Injection valves

- Injectors

- Filters

- Chain tensioners

- High-pressure pumps

- Fuel lines

- Coolant lines

- Oil lines

- Sensors

- Spark plugs

- Screws

- Screw plugs (oil sump)

E-mobility

E-mobility

Electromobility is becoming increasingly important. Due to sensitive electronics, high engine speeds and automatic transmission fluid, the new drive technologies sometimes place new and higher demands on sealing technologies in comparison with classic drive concepts.

As the fast-paced market is developing increasingly rapidly, it often lacks clearly defined standards and established solutions. This results in a need for a high innovation rate and a pressure to launch suitable products on the market as quickly as possible. HUFA meets these requirements in every respect.

Battery casings, coolant lines, hydraulic or pneumatic braking systems, gearboxes or sensors – our constantly growing portfolio includes appropriate metallic seals for a wide variety of areas of e-mobility.

Areas of application – e-mobility

- Battery casings

- Coolant lines

- Sensors

- Isolators

- Potential equalisation

- Gearboxes

- Hydraulic breaking systems

- Pneumatic braking systems

- Screws

- Screw plugs

Injection systems

Injection systems

Injection valves, often also referred to as injectors in diesel engines, administer the correct dose of fuel to vehicle engines before every combustion cycle. Pressures of up to 3,000 bar can occur in modern diesel engines. In order to meet the associated high requirements, purely metallic seals are primarily used in injection technology.

Our high-quality metal seals for injection valves, high-pressure pumps, fuel lines and sensors of petrol and diesel engines ensure that the injection system does not leak in spite of high pressures. Injector spacers, flat or profile seals or bonded seals – we provide appropriate solutions for every sealing requirement in the area of injection systems. Rely on our know-how and the high quality of our products.

Areas of application – injection systems

- Injection valves

- Injectors

- High-pressure pumps

- Fuel lines

- Sensors

Gearboxes

Gearboxes

The gearbox is just as important as the engine in a car’s powertrain. Sitting right on the engine, it converts its engine speed into torque and thus drives the wheels. Changing the gears manually or automatically changes the interaction of various cogwheels inside the gearbox. The result is a variety of gear ratios tailored to the respective driving conditions.

Seals are important for gearboxes in many respect. Firstly, they ensure that the lubricants stay in the casing; secondly, they guarantee that the proverbial sand in the gearbox does not become a reality. Our portfolio for this area includes flat and profile seals as well as bonded seals for gearbox components such as oil and coolant lines, filters or sensors.

Areas of application – gearboxes

- Coolant lines

- Oil lines

- Filters

- Sensors

- Screws

- Screw plugs

Steering systems

Steering systems

The steering gears in cars transfer the rotation of the steering wheel to the tie rod mechanically with the help of the steering column. This causes the tie rod to move to the right or the left, which results in a change in the turning angle of the wheels.

Almost all vehicles now have power steering, which actively assists the driver with the steering and increases comfort and safety. In many cars, the force applied by the driver is enhanced by a hydraulic pump. If this servo pump loses its tightness, the pressure in the steering system falls. This means that the car can only be steered with increased force.

With HUFA metallic seals for power steering pumps, oil lines and steering sensors, you will create the ideal basis for a flawlessly functioning steering system. Our products meet the highest quality standards and are characterised by a long life cycle.

Areas of application – steering systems

- Servo pumps

- Power steering pumps

- Oil lines

- Sensors

- Screws

- Screw plugs

Air-conditioning systems

Air-conditioning systems

Seals provide a pressure-tight closure for refrigeration circuits and therefore contribute to the durability of air-conditioning systems. They are located at the connections for all the components of the refrigeration circuit, from the capacitor to the accumulator/dryer and the expansion valve, through to the evaporator and various optional components such as valves and pressure switches.

Nowadays, CO2 is increasingly used in vehicles as a refrigerant. In comparison with the fluorinated refrigerants that had been used previously, it is environmentally friendly and cost-effective, but requires high pressures of 60 to 130 bar to operate efficiently. At the same time, the small size of the CO2 molecules and the associated high permeation rate present a particular challenge for the guarantee of the tightness of the refrigeration system.

Our metallic seals satisfy the highest standards regarding tightness and the service life, making them perfectly suited for use in the air-conditioning lines, pumps, compressors and evaporators of air-conditioning systems in cars.

Areas of application – air-conditioning systems:

- Pumps

- Compressors

- Evaporators

- Air-conditioning lines

- Sensors

- Screws

- Screw plugs

Braking systems

Braking systems

The braking system is one of a vehicle’s most important safety features. Whilst braking, it is often subject to intense pressure. For example, the braking system of a mid-range car must apply a braking power of more than 500 kW in the event of an emergency stop from 130 km/h. Temperatures of several hundred degrees Celsius arise between the brake disk and the brake pad. The braking power required for this is transferred via the braking fluid by means of high pressure.

HUFA metallic seals keep the braking system completely tight and prevent hydraulic oil from escaping and dripping onto the brake disk. Leaks can lead to a fire, a reduced braking power through to a total failure. Personal injury and damage to the environment can also occur as a result of leaks.

Areas of application – braking systems

- Brake lines

- Hydraulic braking systems

- Pneumatic braking systems

Lines

Lines

Many lines in motor vehicles are high-pressure lines that have to withstand huge pressure. Seals in the line systems are exposed to the same pressures so they must be very robust. In addition, various lines have aggressive media flowing through them, which would corrode seals made of unsuitable materials and thus make them unusable.

With our flat seals, profile seals and bonded seals, you are ideally equipped in this respect. Whether for braking systems, fuel lines or coolant lines, HUFA metallic seals are highly corrosion- and heat-resistant and can withstand enormous strain. This way, they guarantee that the vehicle runs safely and smoothly and ensure that no harmful substances get into the environment.

Areas of application – lines

- Hydraulic braking systems

- Pneumatic braking systems

- Air-conditioning lines

- Fuel lines

- Coolant lines

- Oil lines

Sensors

Sensors

Sensors in vehicles form an indispensable basis for the functioning of a wide variety of active and passive safety systems. In addition to temperature sensors, there are pressure sensors, speed sensors, position sensors and many others. By providing the basic information for a clean and effective fuel combustion in engines and making the reliable functioning of exhaust aftertreatment systems possible, sensors also make an important contribution towards the protection of the environment.

To ensure that sensors permanently provide exact values, they require an adequate seal against air, water and aggressive media such as coolant, fuel or braking fluid. With our many years of experience, we will assist you with the selection of suitable metallic seals and work with you to develop new product solutions for your application if necessary.

Areas of application – sensors

- Braking systems

- Fuel systems

- Speed sensors

- Position sensors

- Refrigeration circuit

- Cooling water circuit

- Oil circuit

- Pressure sensors for various applications

- Temperature sensors for various applications